Best Practices for Maintaining Manure Pumping Equipment Year-Round

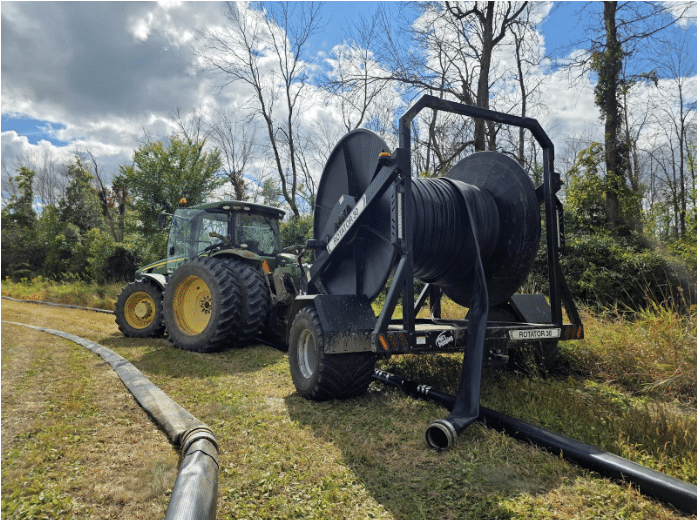

A tractor with hose reel setup for efficient manure pumping, ensuring smooth operation and field coverage.

Maintaining Manure Pumping

Proper maintenance of Maintaining manure pumping equipment is essential for safe, efficient, and reliable application throughout the year. Well-maintained systems save fuel, prevent downtime, and extend the life of expensive pumps, hose, and toolbars.

From preseason inspections to post-season cleanouts, consistent care keeps your operation running smoothly—whether you’re applying manure across Wisconsin, Alberta, or anywhere in between. With a practical maintenance plan, farms and custom applicators can protect their investment and stay ready for every season.

Begin with a Comprehensive Inspection

Every maintenance routine should start with a full inspection of your equipment. Check the layflat hose for cuts, abrasions, or soft spots. Inspect pump housings, bearings, and drive shafts for wear or leaks. Tighten all bolts and inspect the manifold and toolbar for cracks or rust on the fittings.

Before every pumping season, run the system briefly and listen for unusual sounds—knocks, squeals, or vibrations are often the first signs of mechanical issues. Identifying problems early prevents costly downtime later.

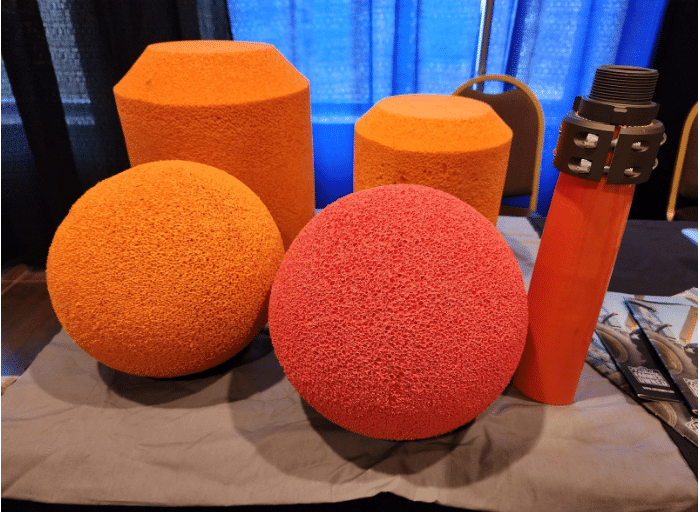

Foam pigs used for cleaning manure hoses, keeping the pumping system clear and ready for the next job.

Clear the Hose and Pump After Each Job

At the end of every application, professional operators clear the hose using a foam ball, known as a “pig,” to push out any remaining manure. This method prevents solids from settling inside and keeps the layflat hose clean without wasting water.

After the hose is cleared, flush the pump and manifold with clean water to remove residual material from internal parts. If the pump will sit idle for a while, coat internal components with a light oil or anti-corrosive solution to prevent rust.

Avoid leaving manure in the hose or pump overnight—proper clearing keeps equipment ready for the next field and helps prevent odor or buildup.

Protect Equipment from Harsh Weather

Because manure pumping equipment operates in the elements, it’s important to shield it from rain, mud, freezing temperatures, and UV exposure.

When possible, store pumps and manifolds indoors. If hoses must stay in the field temporarily, elevate them off the ground to prevent flattening or moisture damage. Before winter, drain water from pumps, hoses, and couplers to prevent freezing and cracking. Cover outdoor components with waterproof tarps to protect from snow and sun exposure.

Prepare for Every Farming Season

Each season brings its own challenges for manure pumping systems:

- Spring: Perform complete system checks before the first pump-out. Inspect suction lines and replace worn seals.

- Summer: Monitor for heat-related hose softening and keep bearings greased to handle long runs.

- Fall: Complete a thorough service after the busy season—change oils, tighten fittings, and repair any worn hose sections.

- Winter: If equipment is stored, rotate pumps or run them briefly each month to keep components lubricated.

Staying proactive between seasons ensures your system starts strong each spring.

Train Every Operator on Proper Handling

When multiple operators use the same equipment, consistent training is critical. Make sure everyone understands proper startup and shutdown procedures, how to ball/clear a hose safely, and what to check before and after use.

A shared maintenance checklist reduces the risk of missed steps and protects both the operator and the equipment. With trained crews, your system performs more consistently and safely.

Create a Maintenance Schedule and Log

The best applicators track everything. Keep a written or digital maintenance log that records daily, weekly, and seasonal checks:

- After Each Job: Clear hose with a foam ball, flush pump, and visually inspect all components.

- Weekly: Grease bearings, check oil levels, and inspect quick couplers and valves.

- Seasonally: Replace worn gaskets, pressure-test hoses, and service the engine or PTO drive.

Keeping accurate records helps catch early wear patterns and ensures nothing is overlooked during busy pumping seasons.

Year-Round Care That Pays Off

Maintaining manure pumping equipment isn’t complicated—but it does take consistency. Regular inspections, hose clearing, lubrication, and weather protection extend the life of pumps and hoses while cutting repair costs.

When your system is cared for properly, you’ll experience smoother pumping days, fewer breakdowns, and better overall efficiency. Reliable equipment means fewer interruptions—and more acres covered when the weather window opens.

👉 Avoid costly downtime and keep your manure system ready for every season. Follow Phil’s Pumping & Fabrication on Instagram for pro maintenance tips, service updates, and the latest equipment innovations.

FAQs

- How often should I inspect my manure pumping equipment?

Inspect at least monthly and always before and after each major pumping job or season. Frequent checks catch issues before they turn into breakdowns. - What’s the correct way to clean out layflat hose?

Use a foam ball (also called a “pig”) to clear manure from the hose after each job. This keeps the hose clean and prevents buildup without manual rinsing. - How do I protect pumps during winter?

Drain all water, store under cover, and run the pump briefly each month to keep internal parts lubricated. Use a waterproof tarp if outdoor storage is required. - When should I replace seals or hose sections?

Replace immediately if you notice cracks, leaks, or soft spots. Worn hoses and seals reduce pressure and can lead to leaks or system failure.