How to Compare Dragline Manure Equipment for Sale Before Buying

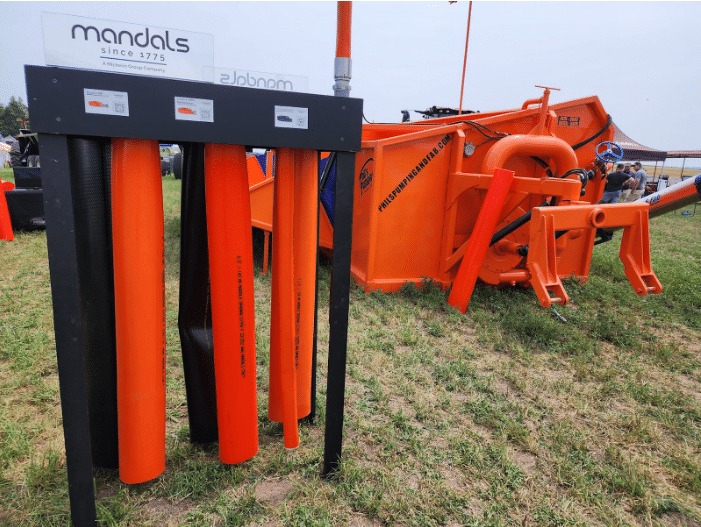

High-quality hoses and toolbars built for dragline systems, improving flow efficiency and application precision.

Best Dragline Manure Equipment for Sale

Choosing the best dragline manure equipment for sale is one of the most important investment decisions for a manure applicator or livestock operation. A properly matched system impacts your efficiency, field performance, and long-term profitability.

Dragline systems have become the preferred solution for large-scale operations because they pump manure directly from storage to the field using a powerful pump, layflat hose, and application toolbar—eliminating the need for constant hauling.

Whether you’re comparing new or used manure equipment, knowing what to look for in pumps, hose, and components will help you make a smart, cost-effective decision. This guide covers the key factors to consider before buying.

Components of a Dragline System and Their Importance

Every dragline setup depends on a few core components working together efficiently: the pump, power unit, layflat hose, and application toolbar. Understanding each part helps you compare equipment confidently.

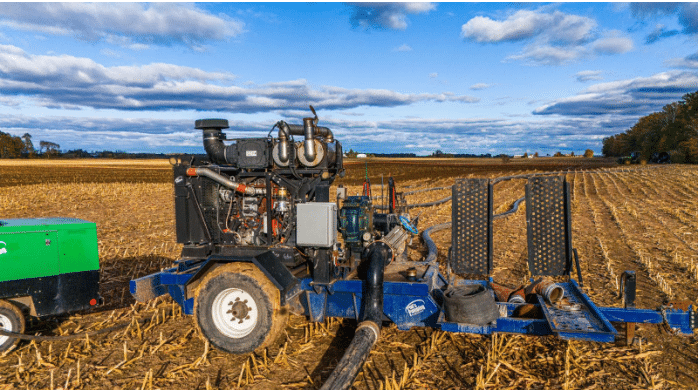

Powerful dragline pump setup efficiently moving manure directly to the field, reducing compaction and labor needs.

Pumps and Power Units

The pump is the heart of the dragline system. It generates the flow and pressure needed to move manure from the lagoon or pit to the toolbar. Pump capacity is measured in gallons per minute (GPM)—the higher the GPM, the faster you can move product across greater distances.

You’ll also want to review the pressure rating (PSI). Higher pressure is necessary for long runs and elevation changes. Many professional applicators use booster pumps along the hose run to maintain pressure on large jobs.

The pump is driven by either:

- A tractor PTO, which is cost-effective and simple to operate, or

- A dedicated power unit or engine, which frees up tractors and can offer more consistent performance on long, high-volume runs.

For custom applicators or large farms, dedicated power units are common because they improve flexibility and reduce downtime during pumping.

Hoses and Their Durability

The layflat hose is what moves manure across the field. There are two primary sections:

- Mainline hose – carries manure from the pit or lagoon to the field edge.

- Drag hose – connects from the mainline to the toolbar and is pulled across the field by the tractor.

Unlike rigid pipes, layflat hose is portable and designed for high-pressure flow while being flexible enough to move with field contours. The best hoses are made from reinforced polyurethane or rubber blends that resist abrasion, UV exposure, and pressure fatigue.

Hose diameter also matters—larger diameters (6″, 8″, or 10″) allow higher flow rates with less friction loss, which improves efficiency and reduces pump strain.

When comparing draglinemanure equipment for sale, check hose condition, manufacturer rating, and coupler integrity. Look for scuffs, punctures, or delamination that could indicate excessive wear.

Application Toolbars

The toolbar determines how manure is applied to the field. Options range from surface splash-plates for top-spreading to injection or low-disturbance toolbars for nutrient placement below the surface.

Injection setups reduce odor, runoff, and nutrient loss, while surface toolbars can be more efficient in certain conditions. Choose based on your soil type, crop system, and local regulations.

Assessing Performance and Efficiency

Application Rate and Uniformity

One of the main benefits of a dragline system is uniform nutrient application. With constant flow, you achieve even coverage across the entire field—something tankers can’t always match.

Ensure the system includes a flow meter and rate control system to monitor gallons per minute and maintain a consistent application rate. Accurate flow measurement protects soil health, prevents over-application, and ensures compliance with nutrient management plans.

Impact on Soil and Labor

Because dragline systems eliminate heavy tankers driving across the field, they significantly reduce soil compaction and preserve soil structure. That translates into better drainage, stronger root growth, and higher yields over time.

Dragline systems are also more efficient in labor. Most setups operate with a two-person crew—one running the pump, one operating the toolbar tractor. Reliable two-way radios or in-cab communication between operators are essential for safety and coordination.

Making a Smart Investment

New vs. Used Equipment

When comparing the best dragline manure equipment for sale, decide whether new or used fits your operation best:

- New equipment provides the latest pump and hose technology, warranties, and customization options. While the upfront cost is higher, it typically means lower maintenance and longer lifespan.

- Used manure equipment can be a great value if properly maintained. Inspect pumps for wear on impellers and bearings, check hoses for abrasion or softness, and test all couplers and valves for leaks. Ask for service records and verify that replacement parts are still available.

A well-maintained used system can perform just as reliably as new at a fraction of the price.

Total Cost of Ownership

Look beyond purchase price. Consider:

- Fuel efficiency and horsepower demand.

- Hose replacement intervals.

- Pump rebuild and maintenance costs.

- Labor and transportation requirements.

A system that’s cheaper upfront may cost more to operate over time if it uses more fuel or wears out faster.

Conclusion

Investing in the best dragline manure equipment for sale is about more than price—it’s about choosing a system that fits your fields, crew, and operation size. Evaluate pump performance, hose durability, toolbar design, and total ownership costs before making your decision.

Phil’s Pumping & Fabrication offers reliable manure pumping equipment solutions—built, maintained, and field-tested across the U.S. and Canada. Whether new or used, we help farmers and custom applicators find systems that move manure efficiently, protect soil health, and keep operations on schedule.

👉 Looking to compare manure pumps and dragline systems? Contact Phil’s Pumping & Fabrication or follow us on Facebook for current inventory, equipment videos, and expert buying advice.

FAQs

- What is a dragline manure system?

A dragline system pumps liquid manure through layflat hose directly to a toolbar in the field—eliminating constant tanker hauling and reducing soil compaction. - What’s the difference between a tanker and a dragline system?

Tankers haul manure in loads to the field, while draglines pump manure continuously through a hose. Draglines save time, fuel, and labor while applying nutrients more uniformly. - What are the most critical components in a dragline system?

Key components include the pump and power unit, layflat hose (mainline and drag hose), and the toolbar used for field application. - How does a dragline system improve soil health?

By minimizing field traffic and compaction, draglines protect soil structure and help crops access nutrients and water more efficiently. - What kind of maintenance does dragline manure equipment require?

Regularly inspect hoses, seals, and pumps for wear, lubricate moving parts, check flow meter accuracy, and clear hose runs after each job to prevent buildup.