The Future of Manure Equipment: Trends Farmers Should Watch

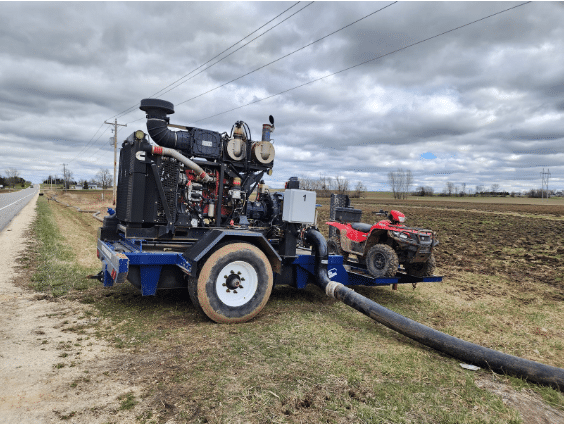

Advanced dragline and tanker manure system showcasing precision application and modern farm efficiency in action.

Future of Manure Equipment

Modern manure handling is entering a new era. Efficiency, precision, and environmental responsibility are driving equipment design more than ever. From dragline systems to tankers and pumps, the industry is moving toward smarter, data-driven technology that saves labor, improves nutrient use, and supports long-term sustainability. Here’s a look at the top trends shaping the future of manure equipment — and how forward-thinking farms and applicators are already adapting.

Precision Application Technology

Precision ag principles are transforming how manure nutrients are applied to the field. Instead of uniform, “blanket” applications, operators are using real-time data and automation to deliver the exact nutrients each acre needs.

GPS Guidance and Variable-Rate Control

Modern dragline and tanker systems now integrate GPS guidance for accurate, repeatable passes across fields. This eliminates overlap, prevents missed strips, and ensures even coverage.

When combined with Variable Rate Technology (VRT), applicators can automatically adjust manure flow rates on the go. Using digital field maps and nutrient prescriptions, VRT systems vary the application rate based on soil type, slope, or crop needs — applying more where nutrients are low and less where they’re already sufficient.

The result: less waste, better crop response, and full nutrient accountability.

Real-Time Nutrient Sensing

The nutrient content of manure can change from one load to the next. To solve this, manufacturers have introduced real-time nutrient sensors that mount directly on tankers or dragline toolbars.

These sensors continuously analyze nitrogen, phosphorus, and potassium levels as manure flows through the system. That data feeds directly into the rate control system, adjusting flow instantly to match the nutrient content being applied.

This technology turns manure from a variable waste product into a predictable, measurable fertilizer resource — helping farms meet nutrient management plans with confidence.

Automation and Remote Monitoring

Automated manure pump trailer ensures precision application and field efficiency with modern dragline systems.

Labor shortages and efficiency demands are pushing the industry toward automation. Modern manure systems are now integrating remote controls, sensors, and digital monitoring to simplify operations and improve safety.

Automated Pump Control

New automated pump control systems use wireless flow and pressure sensors to monitor dragline performance in real time. Operators can remotely adjust pump speed, throttle, and pressure from the tractor cab or smartphone.

These systems help prevent hose ruptures, reduce over-pressurization, and eliminate costly downtime — especially on large field setups with miles of layflat hose.

Autonomous Equipment on the Horizon

Prototype autonomous tractors and spreaders are already in testing. These driverless systems follow pre-programmed GPS paths, making highly accurate applications without human error. As technology matures, these systems could run continuously during short weather windows, maximizing uptime during the application season.

Nutrient Recovery and Conversion

Phil’s Manure Equipment is increasingly being viewed as a renewable resource rather than a byproduct. Equipment innovation focuses on capturing more value from every gallon.

Advanced Separation Systems

High-capacity separators now achieve cleaner separation between solids and liquids. Solids can be composted, used as bedding, or sold, while the liquid fraction is easier to pump and inject.

This technology reduces hauling volume, lowers odor, and simplifies nutrient balancing across fields.

Anaerobic Digestion and Byproduct Utilization

More farms are integrating anaerobic digesters that convert manure into renewable energy. The digestate byproduct still contains valuable nutrients — requiring specialized pumping and application systems.

New agitators, mixers, and pump designs are improving the consistency and usability of digestate, making it easier to incorporate into dragline or injection systems.

Sustainability and Environmental Compliance

Environmental accountability is shaping the design of every new manure handling system. Future equipment will continue to prioritize soil health, runoff reduction, and lower emissions.

Reduced Soil Compaction

Heavy tankers compact soil and reduce yields. The industry is moving toward lightweight designs, flotation tires, and dragline systems that eliminate heavy traffic from fields. These systems protect soil structure while maintaining high-speed application performance.

Predictive Maintenance and Data Tracking

Modern equipment now uses built-in sensors to monitor temperature, pressure, and vibration. These readings predict when parts may fail — allowing repairs before breakdowns occur.

Predictive maintenance reduces downtime during short weather windows and extends the lifespan of expensive components like pumps, bearings, and seals.

The Road Ahead

Manure handling is becoming smarter, cleaner, and more efficient. Farms that adopt these technologies early gain major advantages — from labor savings and improved soil fertility to easier compliance with environmental regulations.

By combining precision application, automation, and nutrient recovery, the next generation of Quality Manure Equipment will help producers close the loop between livestock and crops more efficiently than ever before.

🌱 The future of farming is precision-driven.

Explore modern manure handling systems, GPS-controlled toolbars, and automated pump solutions at philspumpingandfab.com — or follow Phil’s Pumping on Instagram for the latest equipment innovations.

FAQs

- What is Variable Rate Technology (VRT)?

VRT automatically adjusts manure flow rates using GPS and nutrient maps, applying the right amount in each zone to reduce waste and improve crop response. - How does real-time nutrient sensing work?

Sensors measure nitrogen, phosphorus, and potassium levels in manure as it’s applied, allowing instant adjustments for accurate nutrient delivery. - What is the benefit of automated pump control?

Remote pump monitoring reduces labor, prevents hose blowouts, and keeps flow consistent across the field. - Can manure separation reduce hauling costs?

Yes — separating solids from liquids cuts total volume and makes each fraction easier to handle, store, and apply. - Why are dragline systems becoming more popular?

Dragline systems eliminate heavy tanker traffic from fields, reducing soil compaction and improving long-term soil health.