How to Maximize Efficiency with Liquid Manure Pumps on Your Farm

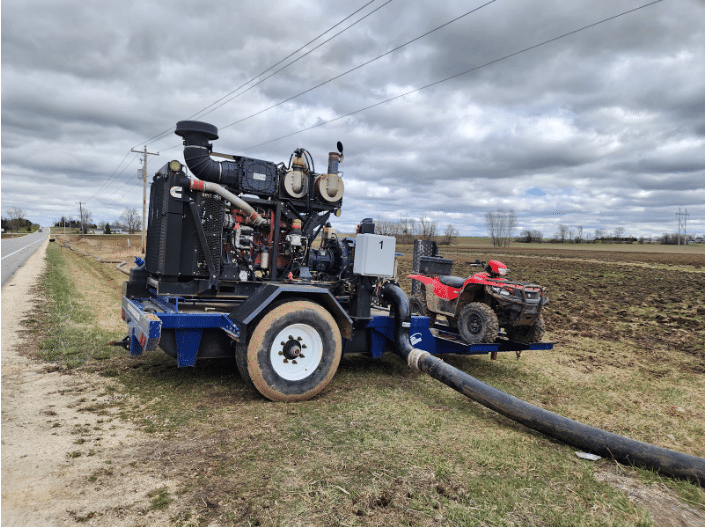

High-performance liquid manure pump setup ensures even nutrient application and reduced field labor.

Manure Pumps

Efficient manure management is one of the most important parts of modern farming. With the right liquid manure pump, farms can move and apply nutrient-rich manure quickly, safely, and with precision. Proper pumping not only saves time and labor—it maximizes fertilizer value, reduces fuel use, and helps protect water quality. For large dairies, beef operations, and custom applicators, optimizing your pump setup is key to getting the most out of every gallon.

Efficient Manure Management

A well-planned pumping system ensures uniform manure distribution, preventing over-application in one area and under-application in another. Consistent application helps crops absorb nutrients evenly and reduces the risk of runoff into waterways.

With the right pump, hose, and flow monitoring, you can apply the exact amount your fields need—turning what used to be a labor-intensive process into a precise, repeatable, and profitable operation.

Choosing the Right Liquid Manure Pump

Selecting the right pump for your operation is the first and most important step toward efficiency. Each type of pump serves a specific purpose:

- Centrifugal Pumps: The most common choice for high-volume, lower-pressure applications. They’re ideal for filling tankers, pit agitation, and transferring manure over shorter distances through layflat hose. Centrifugal pumps are known for durability, ease of maintenance, and consistent flow.

- Positive Displacement Pumps (Piston, Screw, or Diaphragm): Designed for higher pressure or long-distance pumping. They handle thicker, high-solids manure more effectively and maintain pressure over greater distances, but require more maintenance and technical setup.

When selecting a pump, consider:

- Manure consistency: thin slurry vs. heavy solids

- Distance and elevation: longer runs or uphill pumping require more pressure

- Operation size: total volume handled per day or per season

Matching your pump to your conditions ensures maximum efficiency, fewer breakdowns, and longer equipment life.

Applying Manure Efficiently in the Field

Once you’ve chosen the right liquid manure pump, the next step is proper application. Manure should be applied evenly, at the right rate, and at the right time.

Use flow meters and rate controllers to monitor gallons per minute (GPM) and ensure consistent output. This helps you avoid over-application, which wastes nutrients, and under-application, which limits crop yield.

Timing also matters. Applying manure before planting or at key crop growth stages allows plants to absorb nutrients efficiently. Avoid spreading on saturated soil or before rainfall to prevent runoff and nutrient loss.

Regular soil testing is essential. Knowing your soil’s nutrient profile allows you to fine-tune application rates—reducing dependence on commercial fertilizers and improving profitability.

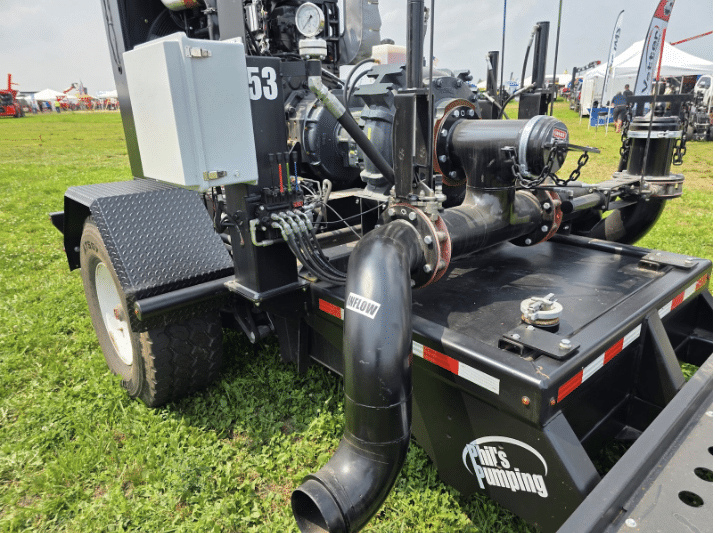

Phil’s Pumping showcases an advanced manure pump engineered for reliable performance and precision control.

Maintenance for Long-Term Pump Performance

Routine maintenance keeps your pump efficient and reliable year after year.

- Daily checks: Inspect for leaks, loose fittings, and worn hoses. Even a small leak can cause fertilizer loss or environmental issues.

- Impellers and seals: These are high-wear components. Regular inspection and timely replacement prevent unexpected downtime during peak season.

- Lubrication: Keep bearings and moving parts greased per manufacturer recommendations. Proper lubrication reduces friction and extends component life.

- Winterization: Before freezing temperatures, drain all liquids from pumps and hoses to prevent cracking. Store the pump in a dry, protected area.

Preventive maintenance not only extends equipment life but also ensures consistent performance when timing matters most.

Maximizing Nutrient Value

Liquid manure contains essential nutrients—nitrogen, phosphorus, and potassium—that drive crop growth. To get the full benefit, manure must be properly mixed and pumped.

Before application, agitate the pit or lagoon thoroughly to create a uniform slurry. This prevents solids from settling and ensures that every load or pumping session delivers balanced nutrient levels across the field.

Precision agriculture tools can enhance this process even further. Some farms use GPS-guided application systems that adjust rates on the go based on soil nutrient maps. This ensures manure is applied exactly where it’s needed, minimizing waste and maximizing yield.

Conclusion

Efficient manure handling starts with the right pump, proper operation, and routine maintenance. Whether you’re filling tankers, running a dragline, or transferring manure between storage facilities, choosing the correct liquid manure pumps saves time, reduces labor, and improves nutrient-use efficiency.

Modern pumps and precision tools make it possible to turn manure from a challenge into a valuable crop resource.

🌱 Efficient, eco-friendly, and built to last—discover how the right manure pump can boost yields and protect your soil. Visit Phil’s Pumping & Fabrication for field-proven Liquid Manure Pumps and expert service support across the U.S. and Canada. Follow us on Instagram for tips and equipment updates.

FAQs

- What size pump do I need?

Choose based on your farm size, manure volume, and pumping distance. High-volume operations or long dragline setups benefit from larger centrifugal or positive displacement pumps. - What causes most manure pump failures?

Clogs from debris, wear on impellers or seals, and inadequate lubrication are the top causes. Preventive maintenance greatly reduces these risks. - How often should I maintain my pump?

Inspect daily during heavy use, perform thorough cleanouts after each job, and replace worn components as needed. Grease and oil according to manufacturer guidelines. - Can the same pump handle different types of manure?

It depends on consistency. Centrifugal pumps handle thin slurry best, while piston or screw pumps perform better with thick or fibrous material. - What’s the benefit of using a flow meter?

A flow meter provides real-time data on application rates, helping you maintain accuracy, reduce waste, and ensure compliance with nutrient management plans.