Liquid Manure Pump Solutions: Improving Efficiency in Manure Management

PTO-powered manure agitator pump designed for fast mixing and transfer from pits or lagoons to fields.

Liquid Manure Pump Solutions

Handling liquid manure is one of the most demanding — and important — aspects of modern livestock farming. The right liquid manure pump Solutions can turn what’s traditionally been a messy, time-consuming task into an efficient, predictable part of field management. With the right setup, farmers can move, agitate, and apply manure faster while reducing labor, fuel use, and environmental impact.

Why Proper Pumping Matters in Manure Management

Liquid manure is full of valuable nutrients that can replace commercial fertilizers and enrich soil health — but only if it’s handled and applied correctly.

A reliable manure pump system ensures even distribution, consistent flow, and clean operation. By transferring manure safely from storage pits or lagoons to the field, farmers minimize waste, prevent nutrient runoff, and create a cleaner, more sustainable operation overall.

How Liquid Manure Pumps Work

A liquid manure pump transfers manure from a pit or lagoon into field applicators, dragline systems, or tanker spreaders.

Many systems also agitate the manure, keeping solids suspended for an even mix and uniform nutrient delivery.

Most pumps used today are:

- PTO-driven — powered by a tractor for high mobility and flexibility in the field.

- Diesel-powered — mounted on portable or trailer units for continuous, high-volume pumping during dragline operations.

These setups are built to move thousands of gallons per minute under pressure, often across miles of lay-flat hose, ensuring steady, efficient flow throughout the application.

PTO-powered manure agitator pump designed for fast mixing and transfer from pits or lagoons to fields.

Choosing the Right Pump for Your Operation

Not all pumps are built for the same job. Your choice depends on manure consistency, storage design, and application method.

- Centrifugal Pumps: Best for thin, liquid manure and high-flow transfer. Commonly used to feed dragline systems or load tankers.

- Agitator Pumps: Mix and transfer simultaneously — ideal for lagoons or pits with solids buildup.

- Vertical Agitation Pumps: Extend deep into storage to keep solids suspended and ensure complete agitation before transfer.

- Booster Pumps: Used in larger systems to maintain pressure and flow across long hose runs.

When evaluating pumps, consider horsepower, flow rate (GPM), and the maximum head pressure needed to handle your distance and elevation change.

Key Features to Look For

A durable manure pump must withstand heavy wear, corrosion, and high flow demands. When purchasing or upgrading, look for:

- Corrosion-resistant materials such as stainless steel or epoxy-coated cast iron

- Replaceable wear parts for long-term serviceability

- Sealed bearings and hardened impellers to handle grit and solids

- Accessible lubrication and inspection points for easier maintenance

- Heavy-duty frames and skids for stability during operation

Every pump leaving Phil’s Pumping & Fabrication is designed, assembled, and field-tested to perform in the toughest real-world conditions — from dairy pits to multi-mile dragline systems.

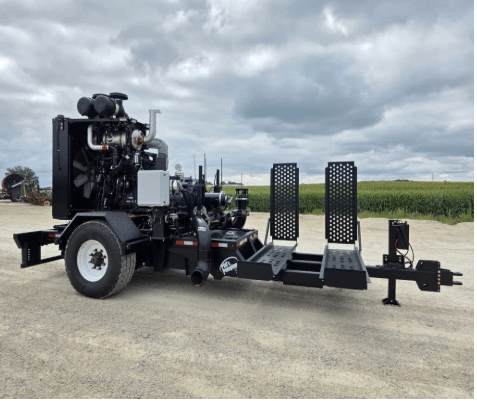

Diesel-powered manure pump built for long-distance, high-pressure pumping in modern farm applications.

Modern Advancements in Pumping Efficiency

Technology continues to improve manure management systems.

Modern setups now include:

- Flow meters to track nutrient output and ensure compliance

- Pressure sensors for monitoring dragline flow and system safety

- Remote or hydraulic controls for quick pump adjustments from the field

These tools make pumping more predictable, efficient, and environmentally responsible.

Maintenance for Long-Term Reliability

Routine maintenance keeps your pump running season after season:

- Inspect hoses, couplers, and seals before each pumping event.

- Clean the pump after every use to prevent buildup or corrosion.

- Grease fittings and bearings regularly.

- Replace worn impellers, seals, or bearings before failures occur.

Following these simple steps prevents costly downtime and keeps your manure system reliable when time matters most.

The Environmental Advantage

Effective manure management isn’t just about efficiency — it’s about sustainability. Proper pumping and agitation ensure that nutrients stay on the field, not in the waterways.

By maintaining consistent pressure, reducing runoff, and applying manure evenly, farmers preserve soil health while protecting local water quality.

Final Thoughts

A liquid manure pump is the heart of every manure handling system. The right equipment can cut labor costs, save time, and maximize the nutrient value of your manure. As farming operations scale up, pumps that are well-built, high-capacity, and easy to maintain will continue to be essential.

From agitation to application — liquid manure pumps are changing the game for farmers. Save money, reduce waste, and work smarter with the right pump system! Find out more on Facebook

FAQs

- What type of manure pump is best for dairy operations?

A chopper or agitator pump is best, as dairy manure tends to be thicker and requires agitation to keep solids in suspension. - Can one pump both agitate and transfer?

Yes. Many modern designs combine agitation and transfer capabilities in one unit, reducing the need for multiple setups. - How much horsepower do I need?

Most manure pumps range from 60 to 200+ HP, depending on flow rates, hose length, and elevation changes. - How can I extend the life of my pump?

Clean after each use, replace worn seals and impellers, and service bearings regularly. Proper off-season storage also prevents corrosion. - Do I need a booster pump for long runs?

If your system runs over a mile or across elevation changes, yes — booster pumps help maintain flow and even application across all zones.