What Determines the Mandals Drag Hose Price? A Complete Cost Breakdown

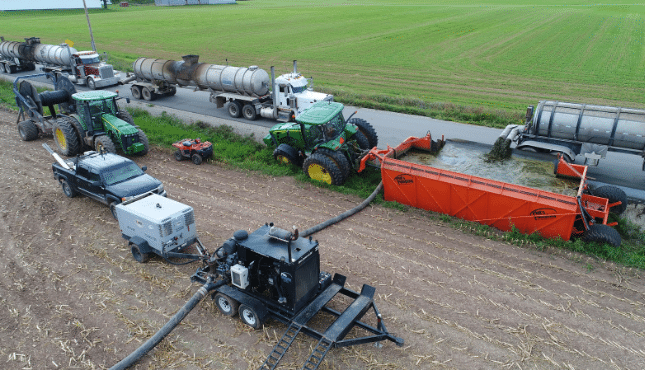

Mandals drag hose rolls designed for durable, high-efficiency manure application in modern farming.

Drag Hose Price

The price of a Mandals drag hose Price like any hose used in manure application systems, depends on several technical and performance-related factors. Understanding these cost drivers helps you make a more informed investment for your operation without compromising efficiency or reliability.

What Is Drag Hose Manure Equipment?

Drag hose manure equipment is a system designed to distribute liquid manure evenly across fields using long, flexible lay-flat hoses. When not pressurized, the hose collapses flat for easier handling and storage; when pumping, it expands to full diameter and carries manure across large distances.

This system is widely used because it supports precision nutrient placement, reduces soil compaction, and significantly cuts down time and labor compared to traditional hauling methods.

Key Forces That Affect the Mandals Drag Hose Price

Hose Material and Build Quality

Higher-quality materials cost more—especially those engineered to resist abrasion, tearing, and chemical exposure. Premium hoses typically use advanced synthetic polymers or reinforced TPU layers that deliver long-term durability under heavy dragline use.

Hose Length and Diameter

Price increases with size.

• Longer hoses require more raw material.

• Larger diameters support higher flow rates and must withstand greater pressure.

Both factors contribute directly to the total cost.

Durability and Resistance

Hoses designed to withstand UV exposure, harsh weather, rocks, stubble, and chemical corrosion generally come at a higher price point. However, these features extend the service life of the hose, reducing long-term replacement costs.

Performance Features

Some hoses include enhancements such as:

• Low-friction liners for improved flow and reduced pumping energy

• Reinforced weaves for better tensile strength

• Anti-kink properties for maneuverability in tight fields

These upgrades improve operational efficiency and lifespan—often increasing the initial cost but lowering downtime and maintenance.

The Power of Quality Over Price

Choosing cheaper Drag Hoses may save money upfront, but low-grade materials often lead to premature wear, ballooning, leaking, or bursting. A high-quality hose ensures smoother manure flow, fewer breakdowns, and better overall performance—especially for farms with demanding terrain or long pumping runs.

Cost Control in Drag Hose Manure Equipment

To manage expenses without sacrificing performance, consider the following:

- Choose the correct hose size for your pumping volume and field layout.

• Prioritize durability, not just low price.

• Evaluate total lifetime cost, including repairs and replacements.

• Consider renting or leasing additional hose during peak seasons if needed.

Simple Tips for Acquiring a Drag Hose System

A complete manure drag hose setup showing pumping equipment and tractors working efficiently in the field.

Before purchasing:

- Estimate your typical pumping volume and distance.

• Ask about warranty coverage and service support.

• Compare feedback from operators using similar hose brands.

• Calculate the full system cost—hose, fittings, installation, and maintenance.

Conclusion

The price of a Mandals drag hose is influenced by material quality, size, durability, and performance features. When selecting drag hose manure equipment, focus on overall value—not just the initial cost. The right hose will help you maximize efficiency, reduce downtime, and increase the productivity of your manure application system.

Discover how the Mandal Drag Hose price is determined! Learn about hose material, size, durability, and performance features to make the best farm investment. Click to read more on our Instagram page!

Frequently Asked Questions

- What determines the price of a Mandals drag hose?

Material quality, hose size, durability, and performance features all influence overall cost. - Why does hose size matter in drag manure equipment?

Larger diameters and longer lengths handle higher flow rates but require more material, increasing price. - How does durability affect cost?

More abrasion-, UV-, and chemical-resistant hoses cost more upfront but reduce repair and replacement frequency. - Can I save money by buying a cheaper drag hose?

Possibly—but cheaper hoses tend to wear out faster and lead to higher long-term maintenance costs. - What else should I consider besides price?

System compatibility, installation needs, warranty, and the hose’s suitability for your farm’s terrain and workload.