The Advantages of Investing in Quality Manure Equipment for Dairy Farms

Manure agitation equipment mixing lagoon slurry for efficient nutrient application on dairy farms.

Quality Manure Equipment

Running a successful dairy farm means managing not only cows and feed, but also the large volumes of manure produced daily. Handling manure efficiently keeps the farm cleaner, safer, and more productive. That efficiency depends on having quality manure equipment for dairy farms designed for real-world reliability and performance.

Modern manure systems turn a major byproduct into a valuable nutrient source. With the right manure pumping equipment, dairy producers can protect the environment, reduce costs, and improve soil fertility—all while maintaining compliance and operational efficiency.

Why Proper Manure Management Matters

Every dairy cow produces roughly 100 pounds of manure per day. Without proper systems in place, that material can quickly become a liability—polluting water sources, creating odor issues, and adding unnecessary labor.

Effective manure management isn’t just about disposal; it’s about nutrient recovery. When handled and applied correctly, manure becomes a renewable fertilizer that supports crop growth and soil health. That’s why more dairies across the U.S. and Canada are investing in manure equipment for sale—from pumps and separators to complete dragline systems.

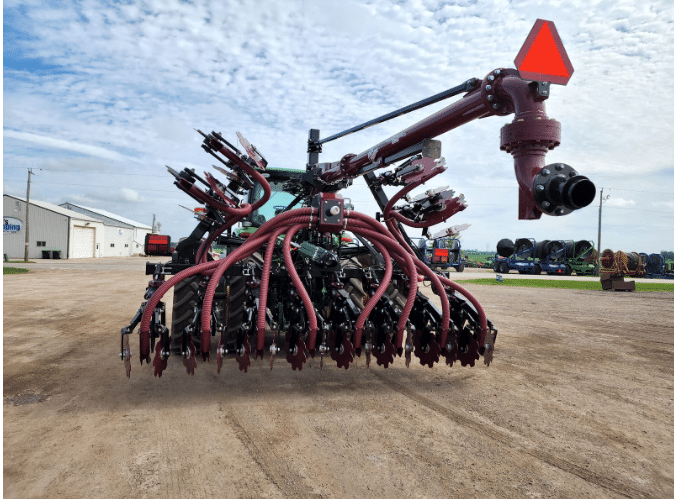

High-efficiency manure toolbar designed for precise nutrient injection and minimal soil disturbance.

Benefits of Quality Manure Equipment

1. Improves Farm Efficiency

Modern manure pumping equipment dramatically reduces labor and speeds up the entire process—from agitation and transfer to field application. Instead of relying on slow, high-traffic hauling, dragline systems pump manure directly to the field through durable layflat hose, covering more acres in less time with fewer machines and operators.

2. Protects the Environment

Efficient pumping and precise flow control prevent over-application and runoff, protecting nearby waterways. Phil’s Manure Equipment with flow meters and calibrated toolbars ensures nutrients stay where they belong—in the soil, not the ditch.

3. Builds Soil Fertility

Manure is one of the most balanced natural fertilizers available. Quality equipment allows for uniform, low-disturbance application, improving organic matter and soil structure while reducing dependence on synthetic fertilizers.

4. Increases Safety and Reduces Odor

Professional systems minimize open exposure and agitation time, reducing odor and gas emissions. By moving manure quickly from storage to field, farms create safer conditions for both workers and livestock while complying with air-quality standards.

5. Long-Term Investment Value

High-quality manure equipment is built to last. While the initial cost may be higher, the reduced downtime, fewer repairs, and lower fuel usage pay for themselves over time. Well-maintained systems provide reliable performance season after season.

Types of Manure Equipment for Dairy Farms

1. Manure Pumps and Agitators

The heart of every system, these pumps move manure from storage to transport or field application. Options include tractor-driven pumps, engine power units, and agitation boats for deep-pit dairies.

2. Layflat Hose and Dragline Systems

Dragline systems use high-pressure layflat hose to pump manure directly to the field. They’re the fastest, most fuel-efficient way to handle large volumes, especially on dairies with multiple acres of cropland nearby.

3. Nutrient Application Toolbars

Toolbars ensure accurate placement—whether surface-applied or injected below the soil. They’re designed for even coverage and compliance with nutrient management plans.

4. Separators and Solids Handling Systems

Manure separators divide solids from liquids for more targeted use. Solids can be composted for bedding or fertilizer, while liquids are recycled for irrigation or pumped through draglines.

5. Storage and Containment Systems

Properly sized lagoons or tanks store manure safely until application windows open, ensuring operations meet environmental and regulatory standards.

How to Choose the Right Manure Equipment

When comparing manure equipment for dairy farms, consider the following:

- Farm Size and Volume: Match pump capacity and hose diameter to herd size and field distance.

- Durability: Look for equipment proven to withstand abrasive slurry, long run times, and varying conditions.

- Maintenance Access: Choose systems with easy-to-service bearings, hoses, and fittings.

- Fuel Efficiency: Power units and pumps designed for high GPM at lower horsepower save operating costs.

- Safety: Equipment should minimize splash exposure and include proper shut-off and pressure controls.

Common Mistakes to Avoid

Even experienced farmers can make costly mistakes when purchasing or operating manure systems. The most common include:

- Buying low-quality, non-reinforced hose that fails under pressure.

- Ignoring flow calibration leads to uneven application.

- Skipping preventive maintenance on pumps and fittings.

- Choosing systems too small for the farm’s daily volume.

- Neglecting training for operators increases wear and safety risks.

Avoiding these errors ensures smoother operation and better long-term returns.

Conclusion

For modern dairies, quality manure equipment isn’t optional—it’s essential. The right system saves time, protects the environment, enhances soil health, and improves the bottom line.

From manure pumping equipment and dragline systems to separators and storage solutions, investing in reliable, well-built equipment keeps dairy operations productive and sustainable across the U.S. and Canada.

When you partner with Phil’s Pumping & Fabrication, you get more than equipment—you get decades of field experience and dependable service that keeps your farm running efficiently.

👉 Explore the latest Manure Equipment for Dairy Farms and learn how Phil’s can customize a solution for your operation. Follow us on Facebook for equipment highlights, demos, and seasonal updates.

FAQs

- Why is manure equipment essential for dairy operations?

It allows farms to handle large manure volumes safely and efficiently while turning waste into a nutrient resource for crops. - Do all dairy farms need a manure pump or dragline system?

Larger farms benefit most from dragline pumping systems, but even smaller dairies use pumps and separators to manage storage and reduce labor. - Is high-quality manure equipment worth the investment?

Yes. It reduces long-term costs by cutting downtime, fuel use, and maintenance while improving efficiency and nutrient recovery. - How should manure equipment be maintained?

Inspect hoses and fittings regularly, grease pumps as recommended, and calibrate flow meters each season to maintain accuracy and reliability. - Can manure equipment reduce odor on a dairy farm?

Yes. Efficient systems minimize agitation and open exposure, which lowers gas release and helps maintain a cleaner, safer environment.