Drag Hose Manure Equipment: Boosting Productivity in Large-Scale Farming

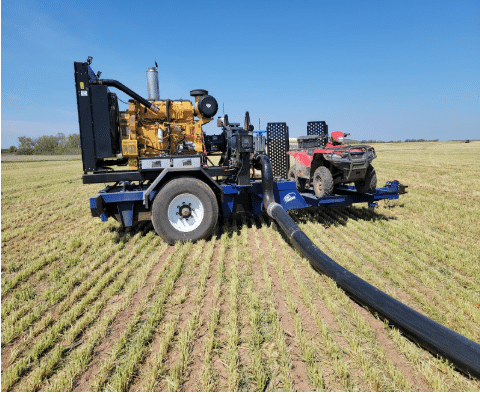

High-powered pump unit connected to drag hose system, streamlining manure transfer directly to the application site.

Drag Hose Manure

Efficiency drives every successful farm, and nowhere is that more evident than in manure handling. Liquid manure is one of the most valuable nutrient sources on the farm—but moving it efficiently across hundreds or thousands of acres requires the right system. That’s where drag hose manure equipment comes in. This technology transforms manure application from a slow, high-labor task into a fast, continuous, and environmentally smart process.

What Is a Drag Hose System?

A drag hose system (often called an umbilical system) pumps liquid manure directly from a lagoon or pit to the field—without hauling tankers back and forth.

A powerful pump setup—typically located at the lagoon—pushes manure through a high-pressure supply hose (like Mandals Superman HVT or Flexitex Extra) and into drag hoses (such as the Mandals Dragman).

An applicator toolbar pulled by a tractor “drags” the hose through the field, injecting or surface-applying manure with precision.

This continuous-flow design eliminates most travel time, reduces fuel costs, and allows applicators to cover large acreages quickly.

Continuous Operation and Time Savings

Traditional tanker systems waste hours traveling between the pit and the field. In contrast, a drag hose system keeps manure moving non-stop once the pump is running.

The application tractor never needs to stop for refills—meaning it can operate all day without interruption.

For large farms or custom applicators, this can mean hundreds of additional acres applied per day compared to tankers.

When weather windows are short or soil conditions are marginal, every hour matters—and drag hose systems make it possible to finish faster and stay on schedule.

Protecting Soil and Increasing Yields

Heavy tankers—often weighing 80,000–100,000 pounds when loaded—can cause severe soil compaction, limiting root growth and reducing yields for years.

Because the heaviest equipment in a dragline system stays at the lagoon, the only machine in the field is the application tractor and toolbar.

The lightweight hose and even weight distribution mean minimal soil disturbance, helping maintain soil structure, aeration, and long-term fertility.

Healthier soils result in better water infiltration, stronger roots, and higher crop productivity—so the same Manure Equipment nutrients go further.

Precision Nutrient Application

Manure isn’t just waste—it’s a renewable fertilizer full of nitrogen, phosphorus, and potassium. Drag hose systems maximize their value by delivering nutrients exactly where crops need them.

Operators can fine-tune application rates in real time to ensure uniform coverage. Many systems also use injection toolbars, placing manure directly into the root zone.

This reduces nitrogen loss to the air and prevents runoff into waterways, improving both fertilizer efficiency and environmental stewardship.

Manure Management at Scale

For large-scale farms, drag hose systems streamline one of the most labor-intensive parts of the operation.

Once set up, a crew can manage massive volumes with just a few operators. Booster pumps can be added to extend the pumping distance several miles while maintaining consistent pressure and flow.

The result: fewer people, fewer machines, and dramatically higher productivity per day.

Precision manure application using drag hose system for efficient nutrient delivery and healthier soil structure.

Why Farmers Are Switching

- Covers more acres per day than any tanker setup

- Reduces soil compaction and fuel consumption

- Lowers labor costs and equipment wear

- Applies nutrients evenly for better crop uptake

- Adapts easily to different soil types and distances

It’s not just a cleaner way to handle manure—it’s a faster, smarter, and more profitable way to manage nutrients on today’s farms.

Ready to invest in efficient manure management? Find out how to choose the perfect dragline system for your farm operations! Check the full guide on our Instagram

FAQs

- How far can a drag hose system pump manure?

With the right mainline hose and booster pumps, systems can pump one to several miles, depending on elevation and hose diameter. - Is it difficult to move or set up a dragline system?

Setup requires planning and specialized equipment, but once a field is prepared, experienced operators can relocate and reconnect lines efficiently between fields. - Can drag hose systems handle thick slurry?

Yes. With proper agitation, modern pumps handle a wide range of consistencies. Homogenizing the pit before pumping ensures smooth, uniform flow and even nutrient distribution. - How does a drag hose system compare to tankers in cost?

Initial investment is higher, but over time, reduced labor, fuel, and equipment wear make the cost per gallon applied significantly lower than with tankers. - What are typical flow rates for drag hose application?

Depending on pump setup, hose size, and elevation, flow rates typically range from 1,000 to 3,000+ gallons per minute, allowing rapid, continuous field coverage.

Smarter. Faster. Greener.

Learn how a full drag hose manure system from Phil’s Pumping & Fabrication can revolutionize your nutrient management program.

Visit our website or follow us on Instagram for the latest field setups and system innovations.