Manure Hose Essentials: Choosing the Right Hose for Efficient Manure Handling

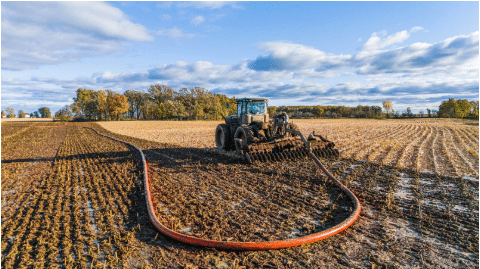

Efficient dragline manure hose system in action — maximizing field coverage with steady flow.

Manure Hose Essentials

A reliable manure hose is the lifeline of any dragline pumping operation. Whether you’re running a few hundred acres or managing a full commercial manure application crew, the right hose can mean the difference between smooth pumping and costly downtime. Choosing the right Manure Hose Essentials ensures safe, efficient, and durable performance in the field — reducing leaks, wear, and unnecessary repairs throughout the season.

Why the Right Hose Matters

Your hose carries thousands of gallons of manure through miles of field each day. It must endure high pressure, friction, and constant movement without splitting, kinking, or collapsing.

A low-quality or mismatched hose can rupture under pressure, slow down pumping flow, or fail during a long pull — costing you hours of cleanup and missed application windows.

Investing in a durable, field-proven layflat hose not only keeps your operation running but also protects your investment in pumps, reels, and toolbars.

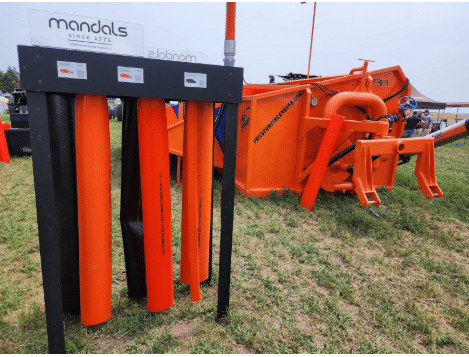

Mandals manure hose display — high-pressure layflat solutions for reliable field pumping.

Understanding the Types of Manure Hoses

In a dragline manure system, there are two main types of hoses — supply hoses and drag hoses. Each serves a distinct purpose in the pumping chain:

Supply Hose (Mainline or Layflat Hose)

This hose transfers manure from the lagoon or pit to the edge of the field. It’s designed to handle high pressure and long-distance pumping. Supply hoses are typically heavier, stiffer, and more abrasion-resistant to handle the constant internal pressure from booster pumps.

Common sizes: 6″, 8″, or 10″ layflat hose, depending on pump size and distance.

Drag Hose (Field Hose)

This hose is connected to the toolbar and is dragged behind the tractor across the field during application. Drag hoses must be flexible, lightweight, and abrasion-resistant, as they’re constantly in motion and contact the ground.

High-end drag hoses — such as Mandals Superman, Dragman, or Flexitex — are designed to maintain flow under pressure while enduring thousands of field hours.

How to Choose the Best Manure Hose

Selecting the correct hose involves balancing pressure rating, flow, weight, and flexibility.

1. Pressure Rating

Your hose must be rated to handle the system’s operating and surge pressure.

- For mainline supply hoses: look for 250–450 PSI working pressure ratings.

- For drag hoses: 150–300 PSI is typical.

Always match hose rating to your pump’s output and booster pressure.

2. Diameter

Hose diameter directly affects flow rate and friction loss.

- 6″ hose suits smaller systems or short runs.

- 8″–10″ hose is ideal for long-distance pumping, higher GPM, and larger toolbars.

Proper sizing ensures steady flow without overloading your pump or causing pressure drops.

3. Durability & Materials

High-quality hoses are built from reinforced thermoplastic polyurethane (TPU) or rubber blends that resist UV damage, abrasion, and chemicals found in manure.

- TPU hoses (like Mandals) are known for light weight, superior flexibility, and long life.

- Rubber hoses offer excellent wear protection but are heavier and less flexible in cold weather.

4. Flexibility and Handling

Drag hoses need enough flexibility to move easily around corners and terrain changes. A good hose won’t kink, even during tight turns or when partially filled. Flexibility reduces strain on the hose reel and toolbar, extending lifespan.

5. Weight and Storage

Lighter hoses are easier to roll, transport, and handle — but they must still maintain high abrasion resistance. Heavier hoses may last longer under extreme pressure but can be more labor-intensive to manage. The best choice is a balanced combination of strength and workability.

Hose Connections, Fittings & Accessories

A manure system is only as strong as its weakest link. Pairing the right couplings, clamps, and fittings with your hose is critical for safety and performance.

- Use high-pressure-rated aluminum or stainless-steel couplers.

- Always verify the hose ID and fitting OD match exactly.

- Quick-connect or “cam-lock” fittings allow faster setup and teardown.

- Add hose savers, guards, or sleeves at stress points (such as reel connections or near the toolbar) to prevent premature wear.

At Phil’s Pumping, custom hose assemblies are available with factory-installed couplers, reducing setup time and ensuring leak-free operation from day one.

Matching Hose Type to Your System

Your manure hose should complement your overall pumping setup — not just fit by size. Consider:

- Pump capacity and pressure output

- Booster pump spacing

- Toolbar width and flow requirements

- Field distance and terrain

For long-distance pumping or multi-field setups, pairing Mandals high-pressure layflat hose with proper booster spacing ensures steady flow, consistent pressure, and even application.

Investing in Quality Pays Off

Cheaper hoses often mean thinner walls, weaker couplers, and more frequent repairs. Each failure risks lost time, environmental cleanup, and downtime during critical windows. High-quality drag and supply hoses last thousands of hours, can handle multiple seasons of demanding use, and maintain pressure integrity under tough conditions.

Your manure hose system is not an expense — it’s an investment in uptime, efficiency, and safety.

Ready to upgrade your manure hose setup?

Phil’s Pumping & Fabrication supplies Mandals layflat, drag, and supply hoses — engineered for professional manure applicators across the U.S. and Canada.

Explore available inventory and hose specs at philspumpingandfab.com or follow us on Facebook for field updates and maintenance tips.

FAQs

- What size hose do I need for manure application?

Most systems use 6″–8″ hoses for standard pumping, while larger commercial setups may use 10″ hoses for long runs or higher flow rates. - How long do manure hoses last?

With proper care and storage, a high-quality drag or layflat hose can last five seasons or more, depending on terrain, UV exposure, and usage frequency. - Can manure hoses be repaired?

Yes, minor damage can be repaired with hose patch kits or coupler re-ends. However, severe damage or delamination usually requires full replacement. - Are all hose fittings interchangeable?

Not always. Hose couplers must match the hose’s inner diameter and pressure rating. Always confirm compatibility before assembly. - What’s the difference between layflat and drag hoses?

Layflat (supply) hoses transfer manure long distances at high pressure, while drag hoses deliver it from the toolbar during application. Both are essential — but serve different functions in the dragline system.