Manure Hose Maintenance Tips to Extend Lifespan and Reduce Breakdowns

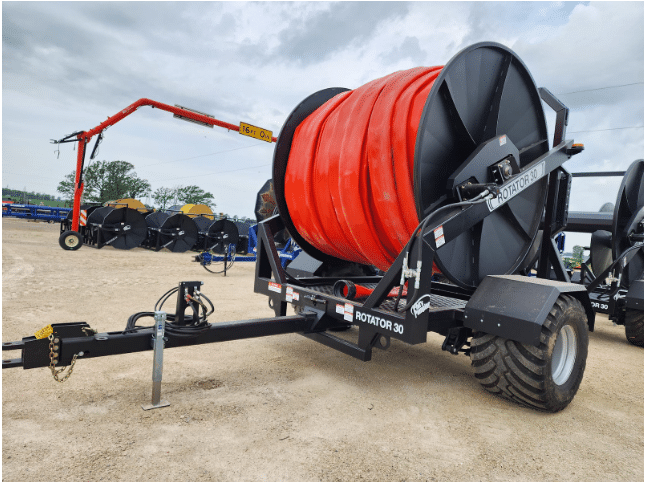

ROTATOR 30 hose reel is designed for efficient drag-hose manure application and easy field handling.

Manure Hose Maintenance Tips

In dragline manure application, hoses are one of the most valuable — and most expensive — components in the system. A well-maintained Manure Hose Maintenance Tips keeps pumping smoothly, prevents failures in the field, and protects your investment. Poor handling, improper storage, or ignoring wear can shorten hose life dramatically, leading to costly downtime and replacements. Below are field-tested practices to help you extend the lifespan of your manure hose and keep your dragline system running reliably season after season.

The Reason Your Manure Hose Should Be in Good Condition

Manure hoses take an enormous beating during application — they’re dragged across gravel, corn stalks, frozen ground, and field edges while under high pressure. They also face:

- Heavy abrasion

- Pressure surges

- UV exposure

- Chemical exposure from manure

- Twisting, folding, and repeated flexing

If hoses aren’t handled, routed, or stored properly, they develop soft spots, delamination, or weak coupler areas.

A hose failure in the field stops the entire operation, often at the worst possible time. Keeping hoses in top condition protects both uptime and profitability.

Industry Standard: How Manure Hoses Are Cleaned After Each Use

After every job, drag and supply hoses are cleared using compressed air, not water.

This is the standard practice across the manure application industry and is the most effective way to keep hoses clean and light for storage.

Here’s how it’s done:

- Compressed air is introduced at the pump or hose-reel end.

- A foam or rubber cleaning ball is pushed through the hose.

- The air pressure propels the ball down the hose, removing residual manure.

- The hose exits nearly clean and lightweight, ready to reel up or transport.

This method:

- Prevents manure buildup and freezing inside hoses

- Speeds up tear-down at the end of the job

- Reduces weight for easier hose retrieval

- Extends hose life by keeping interiors free of solids

No water flush is needed — the air-clearing process is faster, safer, and proven on every major professional dragline crew.

Inspect for Damage Frequently

Before and after each job, walk the hose line and check for:

- Cuts, abrasions, or soft spots

- Exposed reinforcement fibers

- Worn areas around couplers

- Flattened or creased sections from storage

Catching damage early allows for quick patching or coupling repair before it turns into a mid-field blowout.

Avoid Sharp Bends and Kinks

Kinks can permanently weaken a hose’s internal reinforcement.

When laying out or retrieving hose:

- Avoid tight loops and sharp corners

- Guide the ose around obstacles instead of pulling across them

- Train operators on proper layout and retrieval patterns

Even one bad kink can lead to delamination or failure under pressure.

Use Hose Protectors in Wear Zones

Where hoses contact hard or high-friction surfaces — such as:

- Toolbar wings

- Tractor tires

- Field edges or rocks

- Pivot tracks

- Coupler sections

…install hose guards, sleeves, or rubber pads.

These low-cost protectors can add hundreds of hours to hose life.

Use Proper Reel Handling

When reeling hose after pumping:

- Maintain a steady, even reel speed

- Avoid overtightening, which can crush or flatten the hose

- Never drive over a hose during retrieval

Consistent, controlled reel handling prevents stretching and weak spots and makes the layout smoother at the next site.

Why Drag Hose Care Matters

Your dragline system is only as reliable as its hoses.

A single burst hose can:

- Stop the application mid-job

- Cause costly manure spills

- Increase environmental risk

- Create delays during tight weather windows

Proper care ensures the system runs efficiently — keeping your focus on flow rate, coverage, and nutrient accuracy instead of breakdowns.

Rapid Daily Manure Hose Service Checklist

A quick inspection routine before and after every job drastically reduces failures:

- Walk the hose before startup

- Check couplers, clamps, and gaskets

- Inspect known wear points

- Lay out the ose with no sharp bends

- Ensure routing avoids rocks and stubble

- Clear hoses with air and cleaning ball after the job

- Store hoses loosely on reels or flat in long loops

Fast. Simple. Effective.

The Cost of Neglect

Organized drag hoses stored in crates to ensure durability and ready performance in the field.

Skipping hose maintenance almost always leads to:

- Unexpected blowouts

- Uneven application

- Time-consuming cleanup

- Pressure spikes that stress the pump

- Shortened hose life

- Expensive replacements

A few minutes of prevention saves hours — and thousands of dollars — in the field.

Conclusion

Click now for more detais information

Frequently Asked Questions

- How are manure hoses cleaned after use?

After each job, hoses are cleared using compressed air and a cleaning ball. This removes manure residue quickly and prevents buildup — no water flush needed. - Can manure hoses be stored outside?

Yes, but avoid long-term sun exposure. UV light can degrade the outer jacket over time. Store in shade or cover when possible. - What causes manure hoses to crack or delaminate?

Prolonged UV exposure, sharp bends, and dragging over abrasive surfaces are the main culprits. - Are some hoses better for dragline systems?

Yes. Premium TPU and nitrile lay-flat hoses (like Mandals Dragman and Superman PU) are built for abrasion resistance and high pressure. - When should I replace a manure hose?

Replace if you notice repeated leaks, exposed reinforcement, soft spots, or coupler-area failures that can’t be patched safely.