The Evolution of Manure Pumping Equipment at Phil’s Pumping & Fabrication

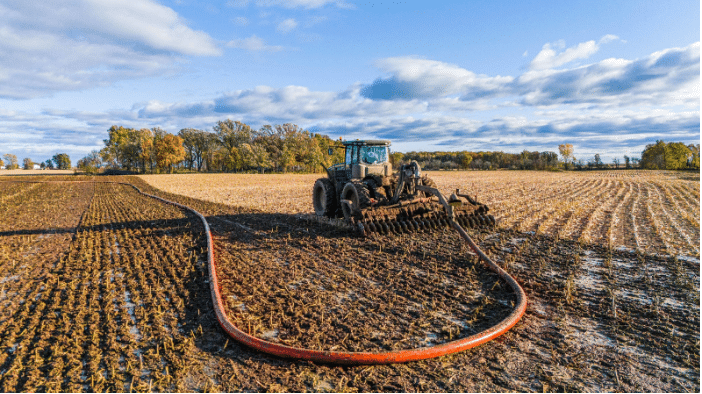

A modern tractor uses a dragline manure pumping system to deliver precise nutrient application across fields, supporting sustainable farming practices.

Manure Pumping

The advancement of manure pumping equipment has completely changed how farms handle large-scale nutrient application. With today’s demand for faster, more efficient, and more sustainable practices, modern systems allow farmers and custom applicators to move and apply manure with precision and consistency.

This evolution highlights how equipment innovation—from agitators and pumps to dragline systems and tankers—has simplified livestock operations while boosting efficiency in the field.

Phil’s Pumping & Fabrication has built its reputation by delivering dependable manure application services and high-performance manure pumping equipment. With solutions including hauling, flow meter calibration, equipment rentals, and maintenance, Phil’s provides customers with the tools and support needed to stay ahead in modern agriculture.

The Progress of Manure Pumping Equipment

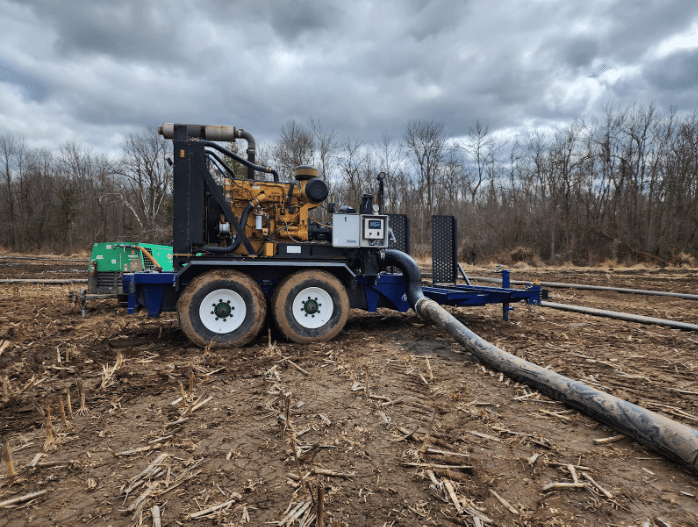

Phil’s advanced pumping setups help farmers cover more acres efficiently with accurate and sustainable manure application.

The rapid growth of manure pumping equipment is driven by larger operations and the need for high-capacity systems. Today’s engineered pumps, hose reels, and toolbar applicators are designed to move massive volumes in less time, with less downtime, and with greater accuracy in the field.

By combining durable designs with modern engineering, Phil’s helps farmers and applicators cover more acres per hour, maintain consistent application rates, and reduce labor needs. The result: a more efficient and sustainable manure handling process that keeps operations running smoothly.

Dragline Manure Equipment and Its Impact

With dragline systems, Phil’s Pumping cuts costs and boosts soil health by applying liquid manure directly from storage.

Phil’s dragline systems have become one of the most efficient ways to apply liquid manure. By pumping manure directly from storage to the field through hose systems, draglines drastically cut transport time and reduce fuel costs compared to traditional hauling.

This method also reduces soil compaction by limiting equipment traffic on fields. With a dragline application, operators can cover more acres faster while ensuring a uniform application that benefits both crop growth and soil health.

Why Equipment Rental Matters

Not every farm requires a permanent dragline or pumping setup. That’s why Phil’s Pumping offers a full line of rental options—giving farmers access to high-performance manure pumping equipment when they need it most.

Phil’s rental fleet is fully maintained and field-ready, ensuring minimal downtime during the busiest manure application seasons. Renting offers flexibility, reduces ownership costs, and gives operators the confidence that they’ll have the right equipment at the right time.

Precision with Flow Meter Testing

Accurate application is critical in today’s farming. Phil’s offers flow meter testing and calibration services to ensure that gallons-per-acre readings are precise and compliant with nutrient management plans.

By verifying flow meters, farmers avoid over-application (which risks nutrient runoff and wasted product) or under-application (which reduces yields). Accurate testing keeps operations in compliance and supports healthier crops and more efficient use of nutrients.

Maintaining Equipment for Reliability

Routine maintenance keeps pumps, agitators, draglines, and tankers operating reliably under tough conditions. Continuous use will cause wear and tear, but with scheduled service and professional repair, Phil’s helps extend the life of manure pumping equipment and ensure dependable performance season after season.

Proactive maintenance also improves safety and reduces the chance of breakdowns during critical application windows. Keeping systems in peak condition saves money, prevents downtime, and ensures a consistent, reliable nutrient application schedule.

Conclusion

The progression of manure pumping equipment shows how farming continues to evolve toward greater efficiency, precision, and sustainability. Whether through dragline systems, rentals, flow meter testing, or routine maintenance, innovation is the driving force behind stronger agricultural operations.

Phil’s Pumping & Fabrication is proud to be at the center of this progress—offering hauling, rentals, testing, and maintenance services that keep farms and applicators equipped for success. Trusted across the Midwest, Phil’s continues to deliver the tools and expertise that modern agriculture demands.

👉 Follow Phil’s Pumping & Fabrication on Facebook for updates, equipment photos, and the latest in manure handling technology.

FAQs

What services support manure pumping equipment?

Phil’s offers hauling, rentals, maintenance, and flow meter testing—each designed to maximize uptime, efficiency, and long-term reliability.

Why is dragline manure equipment considered efficient?

Draglines pump manure directly from storage to the field, cutting down transport time and fuel costs while providing even application over more acres.

How does equipment rental benefit farmers?

Rentals provide access to modern, fully maintained manure pumping equipment during peak demand without the cost of ownership—ensuring flexibility and efficiency.

Why is flow meter testing important in manure application?

Flow meter calibration ensures accurate gallons-per-acre readings, protecting soil health, maintaining compliance, and improving crop yields.

How does regular maintenance improve performance?

Preventive service extends the life of manure pumping equipment, reduces downtime, and improves safety—keeping pumps, trucks, and draglines dependable when needed most.