Manure Pumps for Sale: How to Select the Best Pump for Your Operation

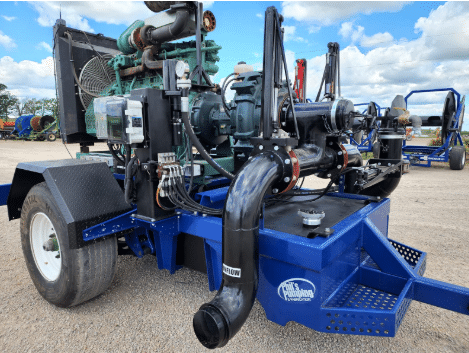

Heavy-duty trailer-mounted manure pump engineered for reliable dragline and pit agitation work

Best Pump for Operation

Efficient manure handling is the backbone of every livestock operation. The right manure pump saves time, reduces labor, and keeps your system dependable throughout the application season. With so many Manure Pumps for Sale, knowing how to select the right one can make all the difference in performance, cost, and longevity.

What Does a Manure Pump Do?

A manure pump transfers liquid or semi-solid manure from storage pits, lagoons, or under-barn systems into field application equipment such as draglines, injectors, or tankers. It’s the powerhouse of your manure system, responsible for both agitation and transfer.

When properly matched to your operation, a good pump maintains even flow, keeps solids suspended, and helps maximize the nutrient value of every gallon applied.

Understand Your Manure and System Design

Every manure system is different. The type of pump you need depends on your manure consistency and how your operation is set up.

- Liquid manure: Ideal for a centrifugal transfer pump, which efficiently handles high-volume, lower-pressure movement.

- Thicker manure or heavy solids: Requires an agitator or chopper-style pump to prevent plugging and keep nutrients evenly mixed.

- Deep pits or lagoons: Use vertical agitation pumps for thorough mixing and effective pit management before transfer.

If you’re running a dragline system, make sure your pump can handle the flow, pressure, and distance required to maintain even application through lay-flat hose and toolbars.

Pump Power and Flow Capacity

A manure pump’s horsepower and flow rating determine how effectively it moves material through your system.

- Choose a unit with enough horsepower (HP) to maintain a steady flow without strain.

- Match gallons per minute (GPM) capacity to your operation’s distance, hose size, and elevation changes.

- For long runs or high-pressure needs, consider a setup that allows for booster pumps down the mainline.

Phil’s Pumping & Fabrication offers pumping units designed to deliver reliable, high-volume flow across miles of hose with consistent field pressure.

Build Quality and Durability

Manure is extremely harsh on equipment — abrasive, corrosive, and heavy. The pump must be engineered to withstand it.

Look for:

- Cast iron or stainless steel housings for corrosion resistance

- Hardened impellers and seals that handle grit and solids

- Heavy-duty bearings and reinforced frames for long life

- Accessible service points for quick greasing and cleaning

Phil’s Pumping & Fabrication builds and services pumps that are proven in real-world conditions — season after season of high-performance use.

Ease of Maintenance and Service Support

Downtime during pumping season can be costly. Choosing equipment that’s easy to maintain and backed by dependable service keeps your operation running smoothly.

- Look for pumps with quick-access covers and replaceable wear parts.

- Confirm parts and service availability before you buy — Phil’s offers full in-house rebuilds, seal replacements, and emergency repairs.

- Choose a manufacturer that understands agricultural timelines and can respond quickly during critical application windows.

The quality of support behind your pump is just as important as the pump itself.

Precision manure application boom ensures even nutrient distribution during dragline pumping

Selecting the Right Pump Type

Here’s how different pump types fit within a manure handling system:

|

Pump Type |

Primary Function |

Best Use Case |

| Centrifugal (Transfer) Pump | Moves liquid manure long distances | Dragline or tanker loading |

| Agitator Pump | Mixes and transfers manure simultaneously | Lagoon or pit agitation |

| Vertical Agitator Pump | Deep-pit mixing and loading | Stationary pit or lagoon setups |

| Booster Pump | Maintains flow and pressure over long runs | Large-scale dragline operations |

| Submersible Electric Pump | Fixed pit or barn recirculation | In-barn transfer only (not for dragline use) |

Submersible pumps are best suited for stationary in-barn or confined pit transfer systems. For dragline operations, centrifugal and agitator pumps for sale remain the industry standard.

Energy Efficiency and Performance

Rising fuel costs make pump efficiency more important than ever. Look for:

- Optimized impeller design for high output with lower horsepower

- Pressure control systems that maintain flow consistency across fields

- Remote monitoring options to track performance in real time

Phil’s Pumping & Fabrication designs and tests its pumping systems to maximize power while minimizing energy use — helping you save both fuel and time.

Final Thoughts

A manure pump isn’t just another piece of equipment — it’s the heart of your manure management system. The right pump provides reliable flow, consistent application, and fewer breakdowns. By matching pump type to your manure consistency, distance, and field setup, you’ll get a system that performs efficiently for years. Phil’s Pumping & Fabrication delivers durable, field-tested manure pumps backed by service and support you can count on.

Make manure management easier with the perfect pump! 💧 Discover how to pick a durable, powerful, and efficient Manure Pump — check it out now on Facebook!

FAQs

- How long should a manure pump last?

A well-built and properly maintained manure pump typically lasts 8 to 15 years, depending on use and material type. - What’s the difference between an agitator and a transfer pump?

An agitator pump stirs and moves manure at the same time, keeping solids suspended. A transfer pump simply moves pre-mixed liquid from storage to application. - Can one pump handle both slurry and liquid manure?

Yes — certain centrifugal and chopper-style pumps are built for both. Always confirm performance ratings before switching between materials. - How often should I service my manure pump?

Perform quick inspections every few months and a full service before each major application season to avoid downtime. - Which is better — PTO-driven or electric?

PTO-driven pumps are ideal for portable, high-volume dragline work. Electric pumps are used in stationary pit setups for simple transfer or recirculation.