Choosing the Right Portable Air Compressor for Clearing Layflat Hoses, Drag Hoses, and Toolbars

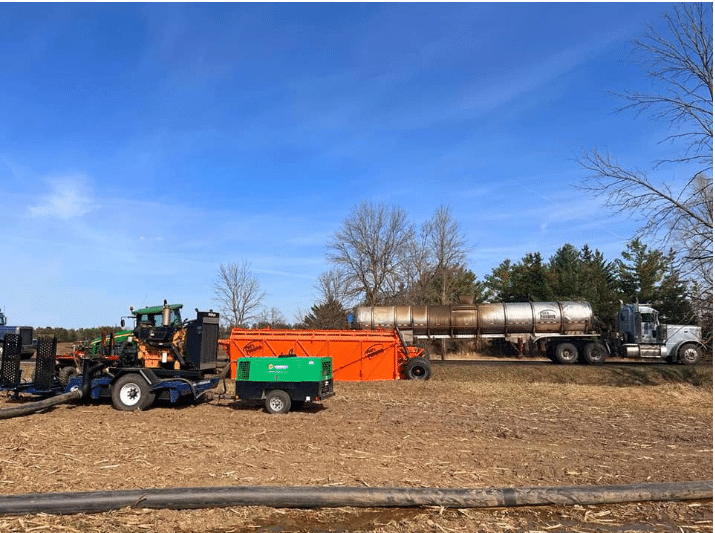

High-performance portable air compressor ensures clean and empty drag hoses for efficient manure pumping.

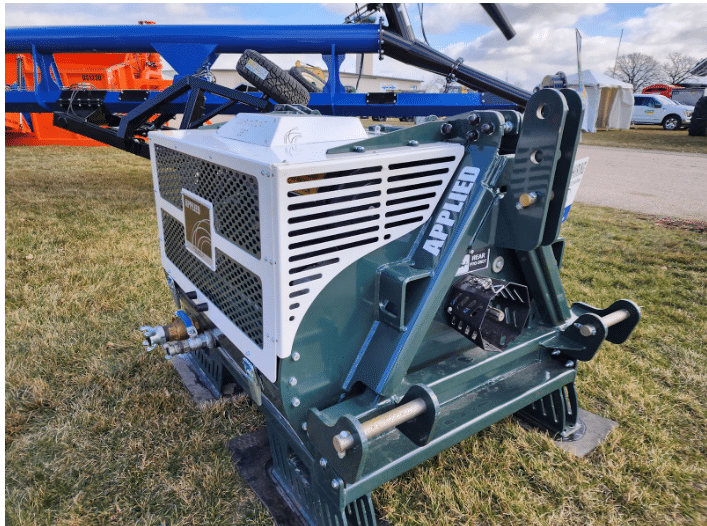

Portable Air Compressor

In modern manure pumping operations, a portable diesel air compressor is an essential cleanup and maintenance tool. Once the application is complete, the compressor is used to clear out layflat hoses, drag hoses, and toolbars, ensuring that every part of the system is empty, light, and ready for transport or storage.

Proper clearing not only saves time during reel-up but also protects hoses from internal buildup, freezing, and premature wear.

Why Air Compressors Matter in Manure Pumping

After hours of pumping, residual manure remains inside layflat hose lines, manifolds, and toolbar sections. That leftover material adds hundreds of pounds of unnecessary weight and can cause freezing or hose degradation if not removed.

A portable Air Compressor Tractor ensures the system is fully cleared by providing high-volume, consistent airflow to:

- Purge layflat and drag hoses after each pumping job.

- Push cleaning balls (“pigs”) through the hose to remove leftover manure.

- Clear toolbars, valves, and distribution manifolds before transport or winter storage.

- Dry out fittings and couplers after washing to prevent rust and corrosion.

This step is a key part of every professional applicator’s cleanup process — ensuring hoses last longer and the system stays reliable through every season.

Airflow and Pressure Requirements

The performance of a compressor in manure applications depends on air volume (CFM) and air pressure (PSI):

- CFM (Cubic Feet per Minute): Determines how much air the compressor can deliver. Higher CFM allows you to clear longer runs of 6″, 8″, or 10″ layflat hose faster and more effectively.

- PSI (Pounds per Square Inch): The air pressure used to move the manure and cleaning ball through the hose. Most operations run between 100–150 PSI, depending on hose size, run length, and field layout.

- Horsepower (HP): Impacts how consistently the compressor maintains airflow under load.

For most applicators, 185–400 CFM diesel compressors are standard for clearing drag hose systems efficiently.

Choosing the Right Compressor for Your Setup

High-performance portable air compressor ensures clean and empty drag hoses for efficient manure pumping.

The correct compressor size depends on your hose diameter, total length, and how often you pump:

- Mid-size farms or short runs (up to ~1 mile of 6″–8″ hose):

A 185 CFM diesel compressor provides adequate airflow for consistent hose clearing.

- Large commercial applicators or long runs (1+ mile of 8″–10″ layflat hose):

A 300–400 CFM compressor delivers the volume and pressure needed to push cleaning balls quickly through extended hose runs.

- Winterization and equipment prep:

Larger compressors make it easier to purge toolbars, valves, and transfer lines completely before freezing conditions.

Clearing Layflat and Drag Hoses Safely

Clearing hoses with compressed air is straightforward but must be done carefully to avoid pressure spikes or hose damage. Follow these best practices used by professional applicators:

- Stand clear of hose ends and outlets while air pressure is applied.

- Use the proper hose ball size for the hose diameter (typically 6″, 8″, or 10″).

- Open valves gradually to prevent sudden bursts of air pressure.

- Monitor air pressure gauges closely during clearing.

- Inspect hose ends, couplers, and clamps before every cleaning cycle.

A well-trained crew and properly maintained compressor make clearing operations safe, efficient, and repeatable.

Clearing Toolbars and Manifolds

Toolbars and distribution manifolds often retain a small amount of manure even after the mainline is cleared. Use compressed air to:

- Purge lines feeding the injectors or dribble bars.

- Blow residual liquid from small distribution hoses.

- Dry fittings and shutoffs to prevent corrosion.

Ensuring the toolbar system is clean and moisture-free helps prevent flow restrictions and uneven distribution during the next application.

Compressor Maintenance for Consistent Performance

Your compressor is a hard-working piece of equipment that deserves regular attention:

- Check oil, air filters, and fuel levels daily during active use.

- Drain moisture from the air tank frequently.

- Inspect fittings and hoses for leaks before every job.

- Follow manufacturer service intervals for filters, belts, and fluids.

Proper maintenance ensures reliable performance, reduced downtime, and extended compressor life.

Long-Term Benefits of Proper Hose Clearing

Using a quality air compressor to clear layflat and drag hoses pays off season after season:

- Prevents freezing and internal buildup.

- Reduces wear and kinking during reel-up.

- Extends hose and valve lifespan.

- Improves system efficiency and reduces cleanup time.

Clean, empty hoses mean faster tear-down, easier transport, and less maintenance overall — making every field more profitable to service.

💨 Keep your manure hoses and toolbars in top shape!

Phil’s Pumping & Fabrication supplies portable diesel air compressors, hose cleaning balls, couplers, and fittings for professional manure hose clearing systems across the U.S. and Canada.

Visit philspumpingandfab.com or follow Phil’s Pumping on Facebook for field tips, equipment updates, and seasonal service recommendations.

FAQs

- What does a portable air compressor do in manure handling?

It clears layflat hoses, drag hoses, and toolbars after pumping — removing leftover manure and moisture before reel-up or storage. - How much pressure is typically used?

Most clearing operations run between 100 and 150 PSI, depending on hose diameter and run length. - What size compressor is best for manure systems?

A 185–400 CFM diesel unit is ideal for most manure applications, with higher output needed for long hose runs. - How often should hoses be cleared with air?

After every pumping job and before winter storage, to prevent freezing, buildup, and damage. - Why is hose clearing important?

Clearing prevents weight, freezing, and wear on layflat hoses and toolbars — helping extend equipment life and improving daily efficiency.